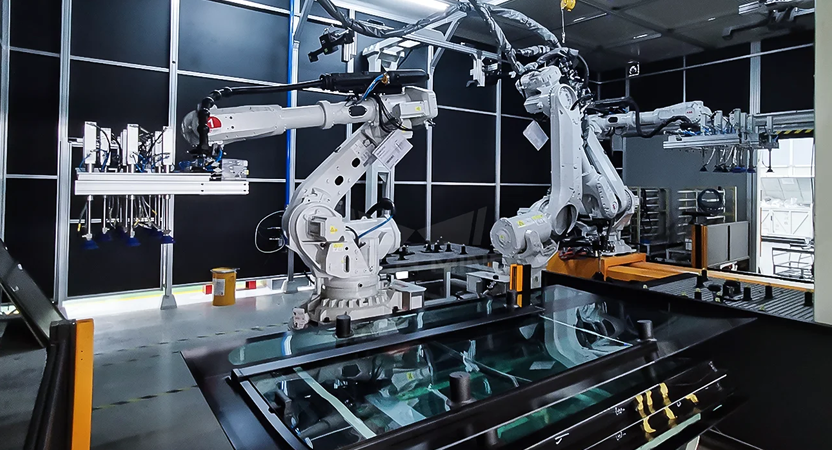

Industrial Automation

Module 1: PLC Programming

– Hands-on training with PLC hardware and software (e.g. Allen-Bradley, Siemens, Mitsubishi)

– Programming exercises and projects using Ladder Logic, Function Block, and Structured Text

– Practice with PLC troubleshooting and debugging tools

Module 2: SCADA System Configuration

– Hands-on training with SCADA software (e.g. Factory Talk, WinCC, In Touch,Aveva,Movicon,Schneider Electric)

– Configuring and designing SCADA systems for industrial automation

– Practice with SCADA system troubleshooting and optimization

Module 3: HMI Configuration

– Hands-on training with HMI software ( Allen Bradley,Siemen,Delta,ABB,Schneider)

– Configuring and designing HMI screens, alarms, and trends

– Integrating HMI with PLC and other devices

Module 4: Motor Control and Drives

– Hands-on training with motor control devices (e.g. VFDs, Soft Starters)

– Configuring and troubleshooting motor control applications

– Practice with motor drive selection and sizing

Module 5: Process Control and Instrumentation

– Hands-on training with process control instruments (e.g. transmitters, sensors, actuators)

– Configuring and troubleshooting process control loops

– Practice with process control strategy development

Module 6: Industrial Automation Project Development

– Designing and developing a complete industrial automation project

– Integrating PLC, HMI, motor control, and process control components

– Troubleshooting and optimizing the project

Module 7: Advanced Topics in Industrial Automation

– Advanced PLC programming techniques (e.g. data structures, advanced math functions)

– Advanced HMI configuration techniques (e.g. scripting, data analytics) – Industry-specific automation applications (e.g. oil and gas, water treatment, food processing, etc)